Case Study

Authentic Design

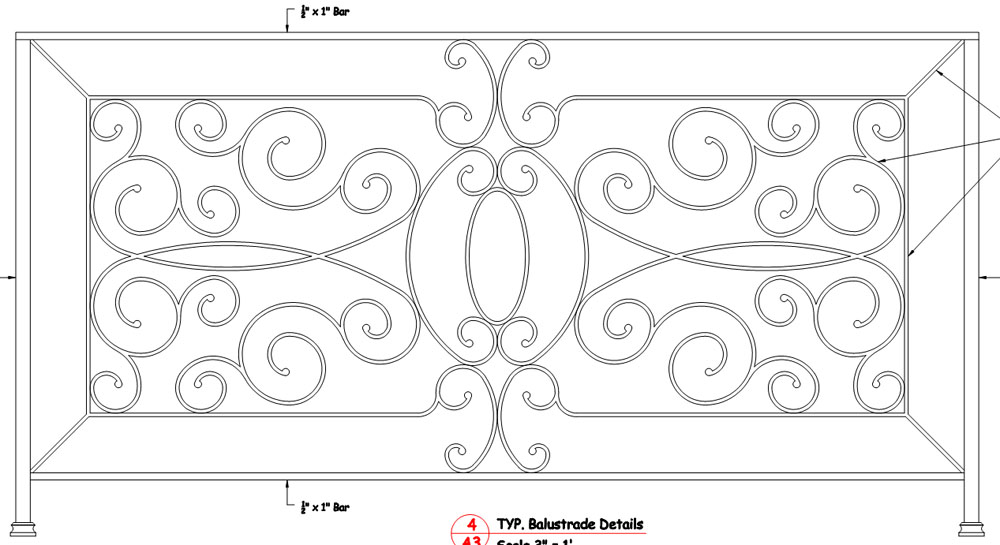

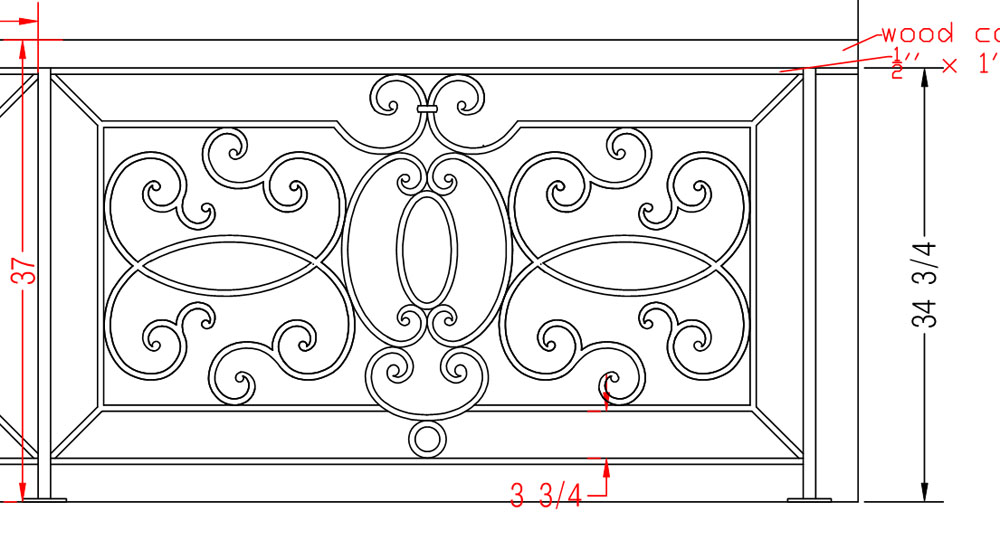

We recreated the entire balcony railing design. We created everything Archimedes. We made all scroll ends in hand-forged roll-ups, which provided excellent authenticity. We evaluated the starting point of every scroll, the space it needed to fill for iron stair railing code to meet the 4” rule, and had the arc be as harmonious as possible. We more than doubled the material thickness so it would portray elegance and character for years.

For the final “wow factor,” the stair railing finish was done in a traditional blackened wrought iron railing finish. The entire thing was blasted to achieve a texture on virgin material. Then it was treated with a special blackening chemical, which turned it black instantly. That was followed by a lot of scotch briting the old-fashioned way by hand, to remove the chemical evaporation residue so the underlying gray/silver of the metal railing could enhance the inherent texture. The entire thing was wiped down and cleaned off and heated to 110°F. The entire project was hand-rubbed with beeswax, just like they did 100 years ago with Samuel Yellin wrought iron. The client, architect, and builder were thrilled with the final result of this beautiful iron stair and balcony railing. It was a perfect fit for their architecturally correct Mainline Philadelphia Home.